Natural Stone: Premium Durability and Timeless Aesthetics for Water Fountain Outdoor Installations

Granite: Freeze-thaw resilience and low-maintenance hardness

When it comes to setting up water fountains outdoors in colder regions, granite just beats everything else on the market. The reason? It's super dense and doesn't soak up much water at all. What makes granite so great for these installations is how its crystals are packed together really tight. This means when winter hits and we get those freeze-thaw cycles, water can't sneak into the stone and cause cracks from inside out. Granite clocks in around 6 to 7 on the Mohs scale, which basically means it can take whatever Mother Nature throws at it for decades without wearing down much. Maintenance is pretty straightforward too most people find they only need to give their granite fountains a good clean once or twice a season, and rarely if ever need those fancy chemical sealants. Plus, the natural speckles in granite hide those pesky mineral buildup spots that show up over time, plus the textured surface actually helps prevent slips near fountain basins where water tends to pool.

Marble and limestone: Elegance versus porosity, staining, and biological growth risks

Water fountains made from marble and limestone definitely have that timeless look many people want outdoors, though they require quite a bit of upkeep. These stones contain calcium carbonate which means they soak up more water compared to granite, and this makes cracks likely during those freeze-thaw cycles we get in colder areas. Because they're so porous, they tend to stain easily from water containing minerals, plus algae grows on them pretty fast in damp weather. If not sealed at least every six months, acid from rain starts eating away at the surface, gradually weakening everything. While marble and limestone work well in dry regions or places with Mediterranean style climates, anyone putting one near running water needs to be ready for regular cleaning and maintenance just to keep it looking decent over time.

Concrete and Cast Stone: Balanced Strength, Customization, and Value for Water Fountain Outdoor Use

Reinforced concrete: Structural reliability and design flexibility in diverse climates

Reinforced concrete stands out because it's both tough and flexible when it comes to designing outdoor water fountains that work well in different weather conditions. The steel inside actually stops cracks from forming when temperatures swing wildly, which makes all the difference in places where it gets really hot during the day and cold at night. Concrete can be shaped just about any way someone wants it, whether they're going for those old fashioned multi-level designs or something sleek and contemporary. With good sealing done right, these fountains often stick around for more than 25 years even in damp climates. Plus there's another benefit nobody talks about much but matters a lot: the material's ability to absorb heat keeps pond water cooler throughout the day, so green sludge doesn't grow as fast in spots where sunlight beats down hard.

Cast stone: Cost-effective realism with engineered weather resistance

Cast stone gives the same natural stone appearance but costs around 40 to 60 percent less money. Plus, it's much more consistent in quality and lasts longer than many people expect. The manufacturing process involves adding special polymers and compacting the mix through vibration techniques. What this does is create material with very low porosity and pretty dense structure, somewhere around 140 pounds per cubic foot or more. It also meets those ASTM standards for strength requirements, typically hitting at least 6,500 psi compression strength. Because of its uniform makeup, these products resist damage from freezing weather, stubborn mineral stains, and even harsh salt air conditions found near coastlines. That makes them work well in places where traditional stone would struggle. When fountain installations get proper sealant treatment on surfaces, they can keep looking good and holding up structurally for two decades or more. For landscape designers looking for something that combines beauty with practicality, cast stone offers a solid alternative to expensive quarried materials without sacrificing long term performance.

Metals: Long-Term Performance and Distinctive Character for Water Fountain Outdoor Applications

Bronze: Self-protecting patina development and architectural longevity

Bronze works really well for outdoor fountains because it develops this natural protective coating called a patina when left outside. What happens is that over time, the metal reacts with air and moisture, creating a layer that stops rust from forming. No need for those fancy protective sprays or coatings either. The surface keeps changing as seasons pass, giving each fountain its own unique look while still staying strong enough to handle whatever weather comes its way. A good quality bronze fountain properly set up can stick around for over half a century even in places where weather gets pretty rough. Maintenance isn't complicated at all – just give it an occasional wipe down with something that's neutral on the pH scale, and it will keep looking great without much effort.

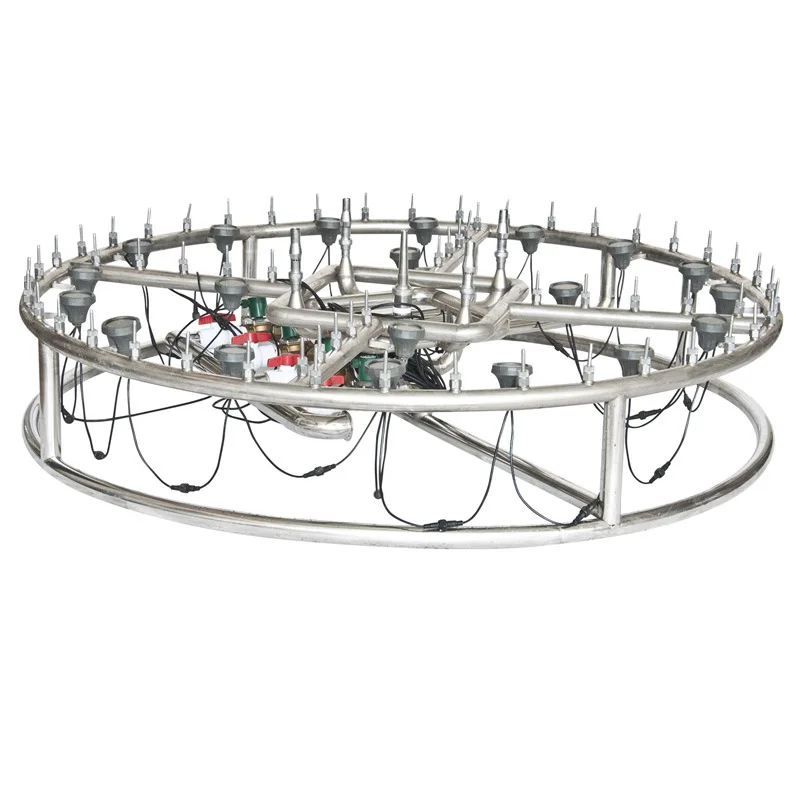

Stainless steel (304 vs. 316): Corrosion resistance benchmarks for coastal and high-humidity sites

Stainless steel stands up well in tough outdoor settings where regular metals would fail. The 304 grade works fine for places away from the coast, though it doesn't handle chloride corrosion very well at all. When dealing with beachfront properties or roads where they sprinkle salt to melt ice, 316 becomes necessary. This version contains about 2 to 3 percent molybdenum which makes it much better at fighting off those pesky pits and crevices that start corroding things apart. Field tests indicate that 316 can last roughly three times as long as 304 when sitting in salty air or water. Getting the right type matters a lot for maintaining both strength and appearance over years of exposure to moisture and sea spray.

Synthetic and Composite Materials: Lightweight, Affordable Options for Water Fountain Outdoor Projects

Fiberglass and resin: UV-stable, frost-resistant, and installation-friendly alternatives

Fiberglass and resin composites work great for outdoor water fountains where weight and durability matter most. The UV stabilized versions won't fade or break down even after years in direct sunlight, something regular stones just can't handle. And when winter comes around, these materials stand up to freezing temperatures much better than natural stone alternatives that tend to crack during freeze thaw cycles. Another big plus is how they stop algae from growing on their smooth surfaces, which means cleaning happens less often maybe as little as 40% less according to some studies. Plus being so light makes everything easier from shipping to setting up complicated designs without needing special machinery. What really stands out though is getting premium looking results without paying premium prices, so both homeowners and businesses can enjoy beautiful water features without breaking the bank.

Ceramic and plastic: Limitations in freeze-thaw cycles and long-term UV exposure

Ceramic and plastic fountains might look nice and cost less upfront, but they just don't hold up outside for good. The glazed ceramic stuff tends to soak up water through tiny little pores, which means it cracks when temperatures drop below freezing. We're talking about real problems here too - around seven out of ten ceramic fountain installations start showing damage after just three winters. Plastic is no better actually. Regular plastic starts breaking down from sun exposure pretty quickly, usually within 18 to 24 months, turning all brittle and changing color. And those cheaper resin versions? They barely make it 3 to 5 years in places where there's lots of sun or near the coast before they need replacing. These materials work okay if someone lives somewhere mild and takes them inside during winter, but honestly, nobody wants to deal with that hassle. For areas that experience cold freezes or intense sunlight all year round, ceramic and plastic simply aren't tough enough.

Matching Material to Climate and Maintenance Realities for Optimal Water Fountain Outdoor Performance

Selecting the right material for your water fountain outdoor installation means aligning durability with local climate conditions and maintenance capacity. Freeze-thaw cycles, coastal salt spray, humidity, and intense UV radiation all accelerate wearâso material choice directly impacts longevity and performance.

Climate-specific material recommendations: Arid, humid, freeze-thaw, and coastal environments

- Arid climates: Choose non-porous granite or UV-stabilized fiberglass to reduce cracking and evaporation

- Humid zones: Use sealed concrete or 316 stainless steel to prevent moisture penetration and biological growth

- Freeze-thaw regions: Opt for reinforced concrete or frost-resistant resin composites that withstand expansion forces

- Coastal sites: Select bronze or marine-grade 316 stainless steel, both of which resist salt spray corrosion through protective surface layers

Maintenance roadmap: Cleaning, sealing, winterization, and lifespan extension by material

A proactive maintenance plan can extend a fountainâs service life by 5â10 years and reduce repair costs by up to 60%:

| Material | Cleaning Frequency | Sealing Requirement | Winterization Protocol |

|---|---|---|---|

| Natural Stone | Quarterly | Annual penetrating seal | Drain pumps; cover with breathable tarp |

| Metals | Biannual | Never (self-protecting) | Apply corrosion inhibitor; keep water flowing |

| Concrete | Monthly | Biannual topical sealant | Blow out pipes; add antifreeze to reservoirs |

| Fiberglass/Resin | Quarterly | UV-protectant spray | Store removable components indoors |

Mismatched materials fail quicklyâunsealed concrete spalls after two winters in freezing zones, and porous limestone stains within 18 months in rainy climates. Consistent care tailored to material properties ensures lasting performance and aesthetic appeal.

FAQ Section

Which material is best for cold climates?

Granite and reinforced concrete are highly recommended for cold climates due to their resilience during freeze-thaw cycles.

How often should a concrete water fountain be sealed?

A topical sealant should be applied biannually to concrete fountains, ideally twice a year.

Why choose fiberglass over natural stone?

Fiberglass is lightweight, easier to install, UV-stable, and more affordable than natural stone, making it a great choice for diverse climates.

What maintenance does bronze require?

Bronze requires minimal maintenance; an occasional pH-neutral wipe-down is sufficient due to its self-protecting patina.

Is cast stone more durable than traditional stone?

While more cost-effective, cast stone offers comparable durability through engineered weather resistance and proper sealing treatments.

Table of Contents

- Natural Stone: Premium Durability and Timeless Aesthetics for Water Fountain Outdoor Installations

- Concrete and Cast Stone: Balanced Strength, Customization, and Value for Water Fountain Outdoor Use

- Metals: Long-Term Performance and Distinctive Character for Water Fountain Outdoor Applications

- Synthetic and Composite Materials: Lightweight, Affordable Options for Water Fountain Outdoor Projects

- Matching Material to Climate and Maintenance Realities for Optimal Water Fountain Outdoor Performance

- FAQ Section