Key Hydraulic Factors That Determine Fountain Nozzle Size

Matching Spray Height and Diameter to Nozzle Orifice and Flow Rate

The hydraulic performance of a fountain nozzle depends on precise alignment among orifice size, water flow rate (GPM), and desired spray characteristics. Orifice diameter directly governs flow capacity: undersized orifices restrict volume—limiting height and spread—while oversized openings reduce pressure, causing unfocused dispersion. For example:

| Nozzle Orifice (mm) | Flow Rate (GPM) | Spray Height (ft) | Spray Diameter (ft) |

|---|---|---|---|

| 5 | 10 | 6 | 3 |

| 8 | 18 | 12 | 5 |

| 12 | 30 | 18 | 8 |

When water moves faster through pipes, it creates those nice tall sprays we all want to see, but this only works if there's enough pressure to overcome what gets lost along the pipe run. If someone installs a pump that's too small for the job and then puts on a big opening nozzle, what happens? The water just plops out in these flat, mushroom shaped sprays that don't reach where they should and basically waste electricity. On the flip side, putting tiny nozzles on powerful pumps creates way too much mist. Field tests show this can make water disappear twice as fast in dry areas compared to proper spray patterns. That kind of evaporation loss adds up over time.

Why PSI, Head Loss, and System Pressure Directly Constrain Fountain Nozzle Selection

The system pressure basically equals what comes out of the pump minus whatever gets lost along the way through pipes and fittings. When we talk about head loss, it's those losses from friction inside the pipes, bends and elbows, plus going up hills or over obstacles that can knock down the available pressure somewhere between 15 to maybe even 30 percent. Take a pump advertised at 30 pounds per square inch (PSI) for instance. By the time that water reaches the actual nozzle, there might only be around 21 PSI left. And each pound lost translates to about a 2% reduction in how high the stream can actually reach vertically. So when picking equipment for these applications, it really matters to account for all these factors properly.

- Calculate total dynamic head (TDH) using manufacturer pump curves

- Subtract head loss to determine residual pressure available at the nozzle

- Choose nozzles operating within 80–110% of that residual pressure

Ignoring these constraints risks pump cavitation, inconsistent spray patterns, or unnecessary system upgrades. Professional hydraulic audits help align technical performance with aesthetic intent—ensuring energy-efficient operation without compromising visual impact.

Aligning Fountain Nozzle Size with Your Pump’s Capacity

Calculating Maximum Compatible Fountain Nozzle Size from Pump Curve Data

Pump curves—mapping flow rate (GPH) against pressure head (feet)—are essential for matching nozzles to real-world system capacity. These curves show how performance declines as lift height increases. For example:

| Head Height | Flow Rate (GPH) |

|---|---|

| 1 ft (12³) | 230 |

| 2 ft (24³) | 160 |

| 3 ft (36³) | 125 |

To determine maximum compatible nozzle count:

- Identify your target spray height

- Read the corresponding flow rate from the pump curve

- Divide total flow by individual nozzle demand (e.g., 160 GPH supports eight 20 GPH nozzles)

- Apply a 20% safety margin for pressure losses

A mismatch causes either flow starvation or pump overload. For instance, attempting a 48³ head with nozzles requiring 50 GPH each overloads pumps rated ≥100 GPH at that height. Always verify claims against empirical pump curves—manufacturer “maximum height” ratings often omit realistic flow constraints.

Balancing Aesthetic Intent and Hydraulic Reality in Fountain Nozzle Sizing

When 'Maximum Height' Specs Mislead: Interpreting Manufacturer Data Honestly

The spray height numbers manufacturers list are based on perfect lab settings where everything works just right all the time. Think about it: pumps running at full strength, no changes in elevation, brand new pipes with no buildup. But real world installations tell a different story. Pipe friction builds up over time, pumps wear down after years of service, and those pesky elevation changes always seem to pop up somewhere. Most folks find their actual performance drops somewhere between 15% to 30% compared to what's printed on the box. Take a nozzle advertised for 10 feet of reach? Realistically expect maybe around 7 feet when it's actually mounted and running. Before trusting those spec sheets, always cross check them against what your system is actually producing in terms of pressure and water flow. Marketing materials can be misleading sometimes.

Visual Impact vs. Energy Efficiency: Selecting a Fountain Nozzle Size That Delivers Both

Designing fountains involves balancing showy effects against what's good for the environment. Big nozzles create amazing water shows but they really eat up power compared to smaller ones. We've seen pump energy go up anywhere from 25 to almost 40 percent when using those oversized nozzles. Cutting back on how high the water sprays can actually save a lot of energy too. When we bring spray heights down to around 80% of what they could be, energy costs drop close to half without losing much of the visual impact. The trick is getting the water path right where people actually look. A nicely positioned 6 foot arc tends to impress folks more than some awkward looking 10 footer stuck in the wrong spot. Getting this balance right means creating something beautiful that won't break the bank on electricity bills either.

Practical Sizing Guidelines for Common Fountain Nozzle Types

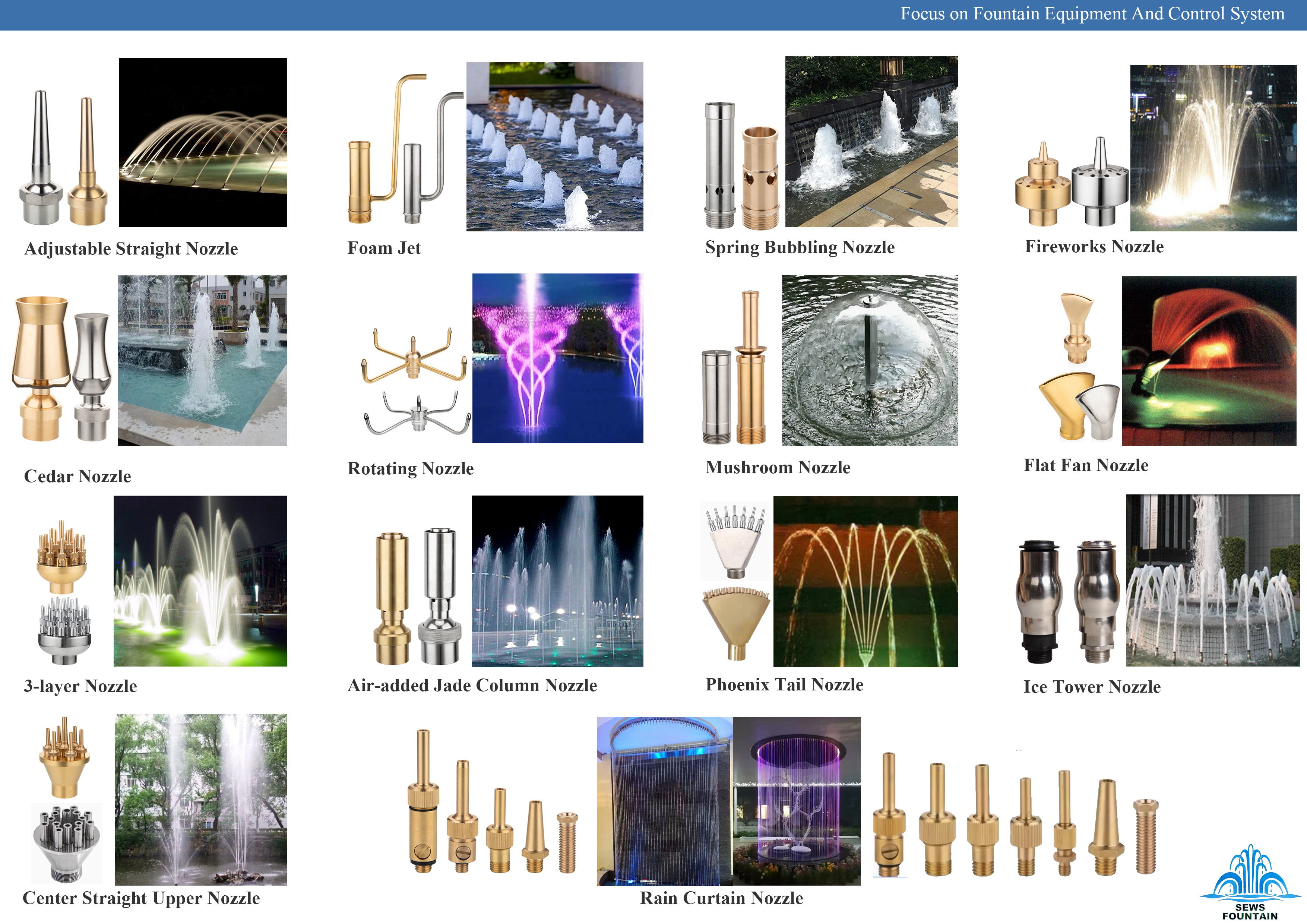

Selecting appropriate fountain nozzle sizes means aligning hydraulic capacity with visual goals. Consider these evidence-based guidelines for common nozzle categories:

| Nozzle Type | Ideal Flow Rate Range | Typical Spray Height | Best Application |

|---|---|---|---|

| Basic nozzles | 5–10 GPM | 1–3 ft | Small decorative ponds |

| Spray nozzles | 10–15 GPM | 4–8 ft | Medium public plazas |

| Tiered nozzles | 15–25+ GPM | 5–12 ft | Large formal gardens |

The amount of water flowing through matters most. When too much water goes through a nozzle, it creates messy splashes and messed up patterns. Not enough water just gives those sad looking sprays nobody wants to see. For homes, simple nozzles work fine since gentle movements can actually make things feel cozier. Commercial areas need different stuff though. Big spray nozzles catch attention without costing tons of extra power. Those fancy tiered setups? They require strong pumps for sure, but when properly matched to the size of the basin, they create really impressive layered effects. Before buying anything, check how well your pump matches what the nozzle maker says about flow rates. Just because something is labeled as a "1 inch nozzle" doesn't mean it will work with any old pump. Getting the right size makes all the difference between a boring mechanical setup and something that looks great while saving water over time.

Frequently Asked Questions

What factors affect the choice of fountain nozzle?

Orifice size, water flow rate, and system pressure are key factors affecting nozzle choice. Mismatches can lead to inefficiencies and unwanted spray patterns.

How do you match nozzles to pumps?

Use pump curve data to determine compatible flow rates and pressures. Account for head losses and ensure nozzles operate within 80–110% of residual pressure.

Why might 'maximum height' claims be misleading?

Manufacturers base these claims on ideal lab conditions. Real installations often experience friction and pressure losses, reducing actual performance by 15-30%.

Are large nozzles more energy-intensive?

Yes, larger nozzles generally require more energy. A balance of visual impact and energy efficiency is necessary for sustainable operation.